Automatic edge banding machine to upgrade handheld edge bander for MDF, block board, solid wood board, particle board, polymer doors, plywood, and aluminum honeycomb panel in assembly line mass production.A furniture edge banding machine is a piece of equipment used in the woodworking and furniture manufacturing industry to apply edge banding to the edges of various furniture components. Edge banding is a process where a strip of material, often a thin veneer or PVC, is applied to the exposed edges of furniture panels to enhance aesthetics, durability, and to cover the raw edges of the core material.The industrial automatic edge banding machine is stable, reliable and durable, and the price is affordable. It is especially designed for furniture and cabinet manufacturers.

Edge bander

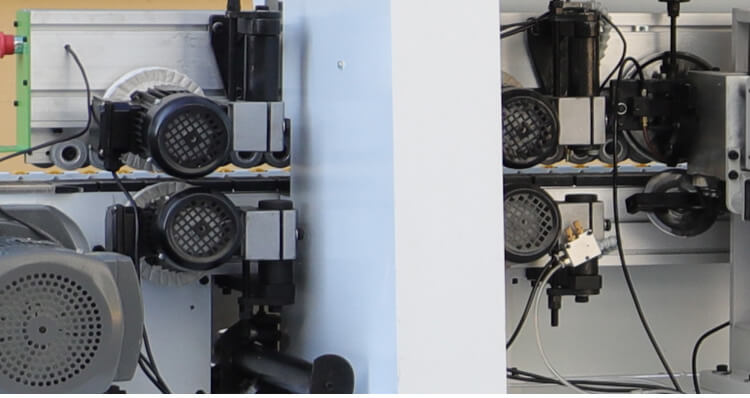

An automatic edge bander is a new type of multifunctional machine tool used for straight edge banding & trimming of plywood, fiberboard, particle board and more substrates. It has compact structure, reasonable layout and beautiful appearance. It adopts sound insulation, dust accumulation port, anti-overload and other devices. It has working units such as front and rear automatic cutting, upper and lower automatic trimming, surface polishing and so on.

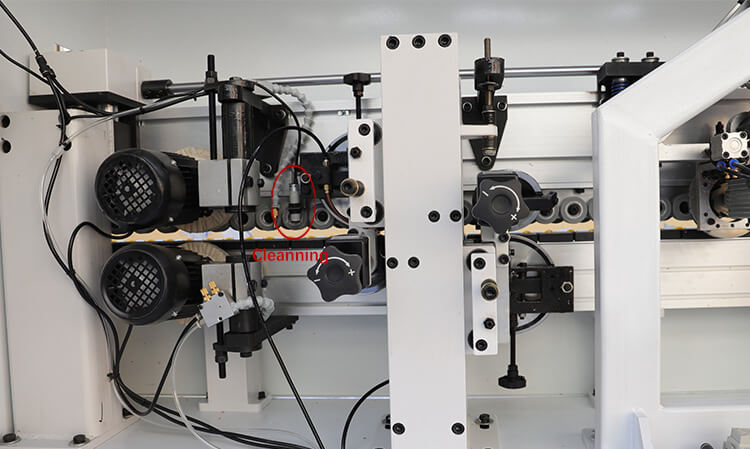

An automatic edge banding machine is composed of the bed frame, the pressure beam device, the conveyor belt transmission device, the rear support device, the edge banding material installation, adjustment, automatic feeding & cutting device, the melt glue gluing device, the edge banding material laminating and pressing device, tightening device, polishing device, electrical control device and pneumatic control device.

Furniture edge banding machines contribute significantly to the efficiency and quality of furniture production, offering a streamlined and automated process for applying edge banding to a variety of furniture components.

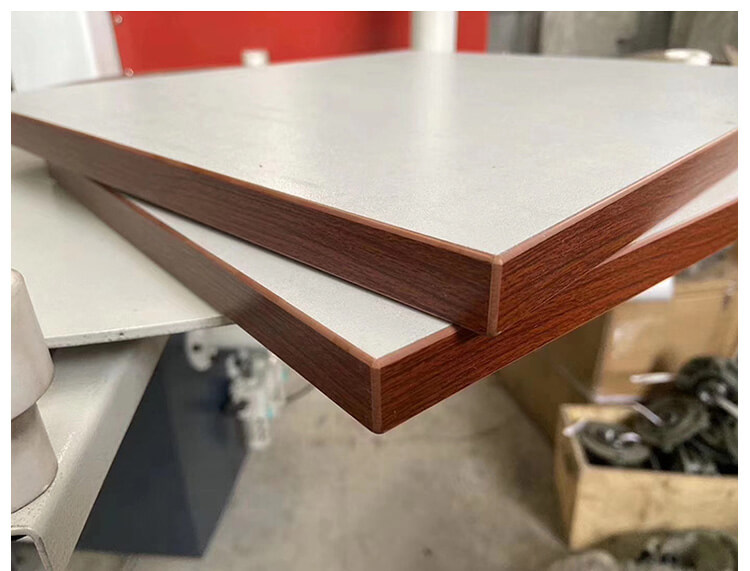

- Edge Banding Process: The machine is designed to automate the edge banding process, which involves applying and attaching the edge banding material to the edges of furniture components. The edge banding material is fed into the machine, and the machine precisely applies adhesive to the edge of the furniture component. Then, the edge banding material is pressed and trimmed to achieve a clean and seamless edge finish.

- Material Compatibility: Furniture edge banding machines are designed to work with various types of edge banding materials. Common materials include PVC (Polyvinyl Chloride), ABS (Acrylonitrile Butadiene Styrene), wood veneer, melamine, and other decorative or protective edge banding tapes. The machine is typically adjustable to accommodate different material thicknesses and widths.

- Automatic Feeding and Cutting: The machine is equipped with automatic feeding systems for both the edge banding material and the furniture components. This ensures smooth and continuous operation without the need for manual intervention. The edge banding material is unrolled and fed into the machine, while the furniture components are fed into the machine for precise edge banding application.

- Adhesive Application: Furniture edge banding machines utilize adhesive systems to apply the appropriate adhesive onto the edge of the furniture components. The adhesive can be hot melt adhesive, which is heated and applied in a molten state, or other types of adhesives suitable for edge banding applications. The adhesive application is typically controlled and regulated to ensure consistent and reliable bonding.

- Trimming and Finishing: After the edge banding material is applied, the machine performs trimming and finishing operations to achieve a clean and smooth edge. Trimming units equipped with cutting blades trim the excess edge banding material, ensuring a flush and precise edge. The machine may also include additional units for scraping, buffing, or polishing to achieve the desired edge finish.

- Control and Automation: Furniture edge banding machines are equipped with control systems that allow for programming and adjustment of various parameters, such as feed speed, adhesive application, trimming depth, and finishing operations. The automation aspect of the machine ensures consistent and accurate edge banding results, reducing manual labor and improving productivity.

- Customization and Versatility: Furniture edge banding machines offer versatility and customization options to meet different furniture manufacturing requirements. They can handle various panel sizes, shapes, and profiles. The machines often have adjustable settings to accommodate different edge thicknesses, widths, and materials. Some advanced models may offer additional features, such as corner rounding, grooving, or profiling capabilities.

- Efficiency and Productivity: The automation and precision of furniture edge banding machines contribute to improved efficiency and productivity in furniture manufacturing. These machines can handle high volumes of edge banding tasks with consistent quality and reduced labor costs. They are widely used in furniture production facilities, cabinetry shops, and woodworking industries.

Applications of industrial edge banding machines

The wood edge banding machine is mainly used for edge banding of medium-density fiberboard, wood board, solid wood board, particleboard, high-gloss board, plywood, etc. That’s the reason why the edge bander is also called the plywood edge banding machine, melamine edge banding machine, MDF edge banding machine, etc.

In terms of wood materials, it can complete birch edge banding, maple edge banding, walnut edge banding, and other wood veneer edge banding work.

The fully automatic edge banding machine has extensive use in middle and large-sized furniture making factories. It has such advantages as stable operation, high automation level, reliable performance, and affordable price. Furthermore, the automatic edge bander machine is an indispensable CNC machine in many furniture production lines.

The manual edge banding machine is good at banding both straight and irregular edges. It is the best edge banding machine for small shops. Besides, it is possible to move the manual edge bander machine from one workplace to another for on-site banding operation.